Please enter the website title

Products

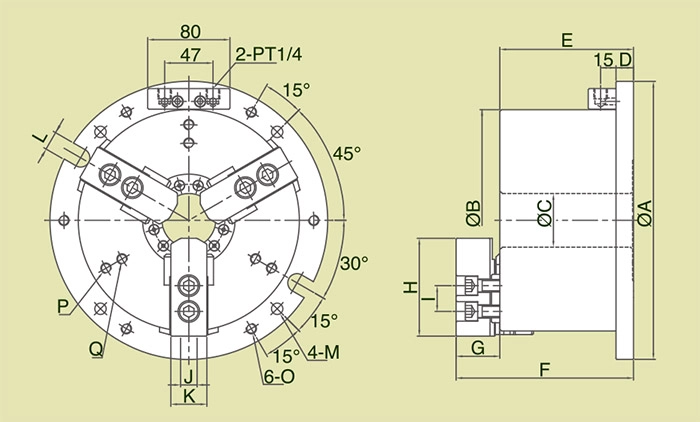

MB Large Through Hole Power Chuck Fixture

Hangzhou Chandox Tosun Import & Export company is a joint venture enterprise, it was built in 2005 and located in city of Hangzhou. It is a Chandox sales company in Mainland, We have certificated ISO9001-2015 quality and management system. We have over forty professional employees to serve our customers, we also have four sales offices located in Shenyang, Yantai, Chongqing and Donguan.

Product Details

With built-in type cylinder, it is ideal for machining application on working table.

1.Rust-proof for Pneumatic Cylinder: Inside wall of cylinder being rustproof treated; cylinder can work under wet or high moisture circumstances without rusty or seized trouble .

2.Dusts-proof and Waterproof: Dust-proof and Waterproof structure prevents work-chips and coolant water from entering into inside of chuck cylinder to maintain its accuracy

3.Benefit of Buit-in Cylinder: The cylinder is connected to chuck itself directly for obtaining better stability, less space, and higher machining eficiency.

| MODEL /SPEC. | A | B | C | D | E | F | G | H | I | J |

| MB-06 | 228 | 173 | 45 | 16 | 118 | 158 | 40 | 73 | 20 | 12 |

| MB-08 | 270 | 215 | 52 | 17 | 130 | 172.5 | 42 | 95 | 25 | 14 |

| MB-10 | 315 | 256 | 75 | 19 | 146 | 190.5 | 46 | 110 | 30 | 16 |

| MODEL /SPEC. | K | L | M | O | P | Q | Piston Area(cm²) | |||

| MB-06 | 31 | 18 | 4-φ11 (PCDφ202) | M10x1.5P | 3-M8x1.25P(PGDφ134) | — | 97 | |||

| MB-08 | 35 | 18 | 4-φ11 (PCDφ243) | M10x1.5P | 3-M10x1.5P(PCDφ150) | 3-M10x1.5P(PCDφ186) | 156 | |||

| MB-10 | 40 | 18 | 4-φ13(PCDφ285) | M12X1.75P | 3-M12x1.75P(PCDφ182) | 3-M12X1.75P(PCDφ232) | 226 | |||

| MODEL /SPEC. | Plunger Stroke (mm) | Jaw Stroke [Diameter] (mm) | Max. Gripping Force kgf (kN) | Max. Hydr.Pressure kgf/cm²(Mpa) | Gripping Range | Weight (kg) | ||||

| MB-06 | 12 | 5.5 | 5040 | (49.4) | 20 | (2.0) | φ20-φ173 | 21.7 | ||

| MB-08 | 16 | 7.4 | 8100 | (79.4) | 20 | (2.0) | φ25-φ215 | 35.5 | ||

| MB-10 | 19 | 8.8 | 12330 | (120.9) | 21 | (2.1) | φ37-φ256 | 54 | ||

★ Reserve the right to modify spcifications

choose an area code